’34 Ford Coupe: Brakes, Fuel Lines and more

Details, details. Progress continues on Bill Evan’s coupe, lately we’ve been going through work that came to us completed, but needed additional attention. The rear end is in the car, but had no venting. Gary machined a fitting and added a vent line. There was also a bit of slop in the front end. We thought it might be in the steering rack, but after investigation it turned out to be in one of the A-Arm’s spherical bearings. Gary machined an adjustment tool and corrected the problem.

We next moved onto the brakes. Installed and supposedly operable, they’d been sitting awhile so we pulled ‘em apart for a check. Good thing we did. The master cylinders were a mess. Whatever brake fluid was used appears to have accumulated moisture, then leaked and coagulated over time. It also etched the walls of the cylinders. We were able to clean up the mount and linkage, but couldn’t save the master cylinders. Fortunately replacements were available.

After encountering a series of cracked flairs we pulled all the brake lines and discovered they’d been incorrectly flaired for the AN fittings used. Some of the lines could be saved, others had to be made up new. The thru-frame unions at the front calipers were also incorrect and not seating against their crush washers. We replaced them, then added residual valves front and rear.

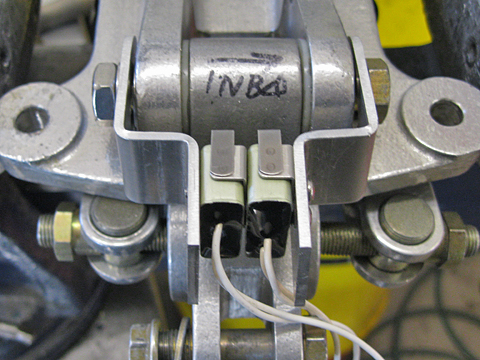

Both the Retro-Tek push-button shifter and the Howell engine control module require a signal from the brake light switch. Nothing’s simple of course, one needs an open signal, the other a closed. Gary made a mount for a set of tandem Mil-Spec microswitches — one Normally Open, the second Normally Closed – that we mounted and wired.

The installation of the push-button shifter eliminated the factory Park/Neutral safety switch so we mounted a third microswitch at the shift arm to ensure the car only starts in Park.

We also re-plumbed the fuel delivery and return lines. In order to fire the motor and get the car over to our shop, it had been set up with temporary fuel hoses. We replaced them with hard lines. We also moved the fuel filter further up the chassis, away from the exhaust — and fabbed a new bracket to better accommodate the fuel lines and battery cables that run past it.

These cables had been temporarily mounted with snap ties, Gary machined new Delrin clamps.

Gary also whittled up a manifold that connects the hard lines that run under the car to the in and out hoses to the intake.

We’ve also completed the installation of the interior insulation, completed the wiring of the engine, and we’re replacing the trans cooler hoses with hard lines, all in anticipation of firing the engine. We’ll keep you posted.

Comments are closed.